3D Printed Device Fights Cervical Cancer in Developing Countries

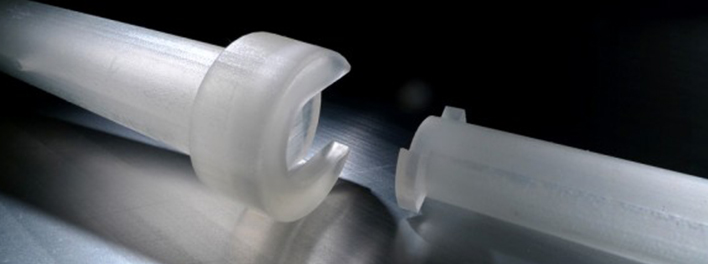

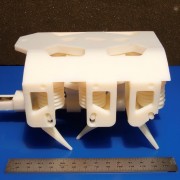

A group of biomedical engineers from Jhpiego and Momo Scientific have developed a device designed to fight cervical cancer. Cervical cancer is responsible for about 275,000 deathseach year, with most of the deaths occurring in developing countries. The new device, called a “CryoPop,” was designed in a CAD program and prototyped on a 3D printer.

The CryoPop is ten times cheaper, thirty times more efficient and more reliable than treatments currently in use. It has the added benefit of using CO2 cartridges (dry ice) to freeze precancerous lesions in the cervix. Dry ice is usually available in developing countries, because it’s used by soda companies which already have an established presence there.

The first CryoPop prototype was printed in the Bioengineering Lab at Johns Hopkins University. As the engineers continued to refine the device, they ran into a number of problems. First, they needed more precision than the printers at Johns Hopkins could handle. The Johns Hopkins 3D printers only had tolerances of 10 -15 thousandths and the support material needed to be manually removed after printing. Next,the engineers tried mechanical machining, but the equipment on hand wasn’t capable of drilling holes deep enough to fit the CryoPop’s design. Then, they tried printing the device in two pieces and gluing them together.

“Having to glue the parts back together created an entire new set of problems for the design’s robustness. And so that was not an optimal solution,” said CryoPop’s Project Manager, Marton Varady. “Plus, the material resulted in a porous device and it affected how the snow [the actual cryogenic element] from solid CO2 was forming.”

Varady began exploring higher resolution 3D printing as an option. He learned that Maryland based company Potomac Photonics had a 3D Systems Projet HD 3000 Plus. He contacted them, and they agreed to print the CryoPop for him.

“The resolution of the [Projet HD 3000 Plus] 3D printer was much higher than what we had in our onsite lab. Working with tolerances in the 1 – 2 thousandths range gave us the parameters we needed to fulfill the design requirement. Plus, we could make the entire part in one piece which increased robustness,” Varady said.

The CryoPop is still in the early phases of testing. Once the testing process is complete, Momo Scientific has plans to distribute the CryoPop throughout India and Sub-Saharan Africa. You can take a look at their mission statement here:

Source: 3D Printed World

Leave a Reply

Want to join the discussion?Feel free to contribute!