NORTHWESTERN UNIVERSITY RESEARCHERS 3D PRINT CERAMIC FUEL CELLS

In additive manufacturing processes, it’s all about speed and precision, and a group of researchers at Northwestern University think creating ceramic fuel cells with 3D printing technology will lead to new fuel cell designs capable of converting a gas into electricity.

Ramille Shah, an assistant professor of materials science and engineering, says her team has developed a set of new inks which could be used by a single 3D printer to output all the various components of a solid oxide fuel cell.

Shah’s TEAM (Tissue Engineering and Additive Manufacturing) lab works on what they call “3D Printable Materials Development and Characterization,” and that’s essentially the search for novel processes for engineering 3D inks and direct ink writing processes.

The lab works on characterization, functional testing, and optimization of 3D printed structures for both biological and non-biological applications like tissue engineering and energy applications. From their facilities on the NU Medical Campus in downtown Chicago, Shah’s group interacts with medical clinicians and surgeons and collaborates with the Materials Science and Engineering faculty for their work on energy, smart materials, aerospace and advanced structures.

Makings such cells requires a cathode, anode, electrolyte, and various interconnects, and Shah says the new inks are a mixture of ceramic particles capable of making it happen. The ceramic particles, up to 90 percent of the final mix, also include a binder and an amalgam of solvents which evaporate at varying rates.

The ink used for the electrolyte and anode is made of yttrium-stabilized zirconia particles. The anode also includes nickel oxide.

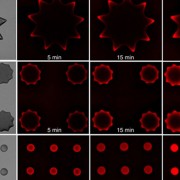

The process goes like this: as the machine prints a line with one ink, a highly volatile solvent in the mix evaporates immediately which allows the printed piece to turn from a liquid to a solid – instantly. As the remaining solvents evaporate more slowly, printed lines are hard enough to maintain their shape, but soft enough to meld with the next layer, joining to form a single part.

The printing itself is done at room temperature but later ‘fired’ at nearly 1250° C to make the part more dense and smoother. Shrinkage is controlled by the composition of the individual inks and iron oxide is added in layers as well.

Adam Jakus, a PhD student working with the Shah TEAM, says very densely packed particles in the printed structure are the result. He adds that using 3D printing to build these fuel cells will prove more efficient than joining separate parts together.

Source: 3dprinterworld.com

Leave a Reply

Want to join the discussion?Feel free to contribute!