BIODEGRADABLE 3D PRINTED METAL BONE SCAFFOLDING

The human mechanism is capable of some amazing functions, but this one boggles the mind. Researchers are saying they’ve developed 3D printed iron–manganese structures for use as bone scaffold material and it actually biodegrades inside the body when their work is done.

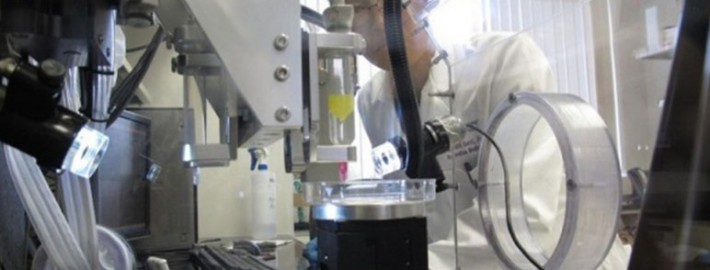

The iron-based alloys have been chosen due to their high strength and ability to slowly corrode and the fabrications use inkjet 3D printing to generate the complex – and customizable – parts from powders which maintained an “open porosity” of 36.3%. That makes them ideal as support structures on which to grow bone.

The iron-based alloys have been chosen due to their high strength and ability to slowly corrode and the fabrications use inkjet 3D printing to generate the complex – and customizable – parts from powders which maintained an “open porosity” of 36.3%. That makes them ideal as support structures on which to grow bone.

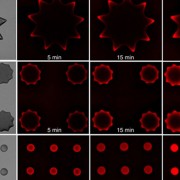

Electrochemical corrosion tests showed that the 3D printed Fe–Mn alloy corrodes much more quickly than scaffolds made from pure iron, and that the similar tensile mechanical properties of the new material are very like those of natural bone.

By printing “pre-osteoblast cells” directly onto the Fe–Mn scaffolds, the scientists found that the degraded scaffolding demonstrated good in vitro cytocompatibility compared to tissue culture plastic. They were also impressed with the ability of the bone cells to infiltrate into the open pores of the 3D printed scaffolds.

The researchers from the University of Pittsburgh Swanson School of Engineering and McGowan Institute for Regenerative Medicine (MIRM) are saying that this process will ultimately be used to create biodegradable tissue repair structures for the human body.

One of 15 projects selected by America Makes, the National Additive Manufacturing Innovation Institute, Additive Manufacturing of Biomedical Devices from Bioresorbable Metallic Alloys for Medical Applications is the work of Prashant Kumta, Howard Kuhn and Patrick Cantini.

The team is working alongside corporate partners ExOne, Magnesium Elektron and Hoeganaes on the $590,000 contract over the next 18 months.

The team is working alongside corporate partners ExOne, Magnesium Elektron and Hoeganaes on the $590,000 contract over the next 18 months.

“Additive manufacturing combines the best of technologies,” said Kumta. “The ability to construct complex structures via computer imaging utilizing a combination of advanced biocompatible and more importantly, biodegradable alloys.”

The project uses medical imaging scans to determine where the scaffolds can do the most good.

“Thanks to computer-aided tomography, or CAT scans, we can directly image a damaged structure like a bone or trachea and construct a biodegradable iron-manganese based scaffold to promote natural tissue growth during the healing process,” Kumta says. “This reduces the risk of disease transmission via methods such as bone grafting, and allows for a more precise framework for the body to heal itself by controlling the degradability of the alloy by careful alloy design and engineering.”

But it’s the novel nature of the materials, biodegradable alloys, which make all the difference as systems to support and deliver biological molecules and antibiotics.

“Although we could create a ceramic or plastic part with additive manufacturing, this is not as ideal as an iron-manganese alloy which is stronger, more ductile and degrades over time to be replaced by new bone,” says Kuhn of the project.

Source: 3D Printed World

Leave a Reply

Want to join the discussion?Feel free to contribute!