British surgeon uses 3D printing to create pelvis for a cancer patient

A British surgeon has used 3D scanning and 3D printing techniques to create a new pelvis for a patient who had lost the whole right side of his pelvis to cancer.

The patient in his sixties had been diagnosed with a rare bone tumour called chondrosarcoma. “Since this cancer does not respond to drugs or radiotherapy, the only option was to remove half of the pelvis,” said Craig Gerrand to Telegraph, a consultant orthopaedic surgeon at Newcastle Upon Tyne Hospitals NHS Trust.

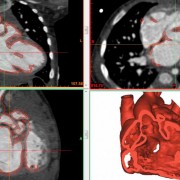

With traditional methods the patient’s pelvis would be replaced by hand-made implants that do not fit perfectly, so Gerrand offered the patient innovative reconstruction using 3D printing. Gerrand and his team scanned the patient’s pelvis allowing them to measure exactly how much bone would be removed. Then the 3D scans were processed and sent to British company Stanmore Implants in Elstree. Specialists at Stanmore Implants used 3D printing to make a bespoke model of a half-pelvis in titanium powder.

The titanium pelvis was coated with a mineral into which the remaining bone could grow. The implant was then robotically inserted into the patient. The surgeon can cut the bone exactly using surgical navigation technology, in which images of the pelvis are uploaded on to a computer to create a model on the screen. Afterwards a standard hip replacement was fitted into the new titanium socket.

Such implants can be made to last longer and have surfaces that mesh better with bone than those manufactured by other methods. The patient is now able to walk with the aid of a stick.

3D printing technology has two beneficial features: 1. It can print specific structures; 2. It is capable of producing porous metal that allows bone to grow into the metal pores, and enhance the strength of the implant.

In August 2013, a Chinese team, led by Dr. Liu Zhongjun at Peking University Third Hospital in Beijing, used a porous 3D printed titanium implant to fit to anatomical structure of a vertebra for a spinal fracture patient.

“In the past we used clinical titanium mesh, but with the growth of bone, titanium mesh could easily get stuck into the bone and cause collapse. 3D printed implants fit the bone completely. And as a result, not only the pressure on the bone is reduced, but it also allows the bone to grow into the implants.”

“In this aspect, 3-D printed implants are more reliable than traditional ones,” Liu said.

Posted in 3D Printing Applications

Leave a Reply

Want to join the discussion?Feel free to contribute!