Metamason Turns to 3D Scanning and 3D Printing To Customize the Respere CPAP Mask

Metamason is a new Southern California start-up looking to help people who suffer from sleep apnea create custom made CPAP masks designed for their specific face and comfort requirements.

Most people assume that sleep apnea is simply what makes a person snore, and other than being a nuisance is relatively harmless. Unfortunately the reality is that when you suffer from sleep apnea, you actually stop breathing for a moment and the snore is your body’s way to jumpstart your body into breathing again. While the obvious risk is to relationships and your ability to get a good night’s sleep, sleep apnea is very hard on your body and considered a leading cause of depression, chronic fatigue, hypertension, heart disease and can contribute to the onset of diabetes and even lead to congestive heart failure.

A CPAP machine sends air into a mask on your face that, when used correctly, will force your airway to remain open, preventing you from snoring and keeping your airway unobstructed. Unfortunately sleeping with a CPAP mask isn’t especially comfortable and up to 50% of patients who require a CPAP machine stop using it due to (dis)comfort issues. As someone who suffers from sleep apnea himself and stopped using his CPAP for this very reason, the Respere is a very exciting development for me personally.

A CPAP machine sends air into a mask on your face that, when used correctly, will force your airway to remain open, preventing you from snoring and keeping your airway unobstructed. Unfortunately sleeping with a CPAP mask isn’t especially comfortable and up to 50% of patients who require a CPAP machine stop using it due to (dis)comfort issues. As someone who suffers from sleep apnea himself and stopped using his CPAP for this very reason, the Respere is a very exciting development for me personally.

Metamason hasn’t just developed a 3D printed CPAP mask however, they’ve developed an entire workflow for scanning, processing and creating the custom masks. Your doctor will scan your face with a state of the art 3D scanner and use an API that compiles that scan with data from your previous sleep studies and thermal imaging of your face into a HIPAA compliant cloud server. Once online, the data is compiled and applied to simulations that allow you and your doctor to create the best mask configuration for your sleep habits and facial structure.

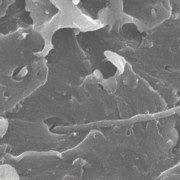

The mask itself is created with an investment moulding process that utilises a 3D print of a wax mold of your mask and then cast it in medical grade silicone. Because the moulds are 3D printed, not traditionally tooled, the cost of fabrication is a fraction of what a custom mask would ordinarily be. The investment moulding process can create very complex cavities that would be impossible with other forms of manufacturing, so the mask would be the exact shape required to help you maintain comfort and an unobstructed airway. Once the mask is printed and cleaned, it’s shipped directly to the customer. Here’s a promotional video overview of the product:

While Metamason is still waiting for approval to start selling the masks, it looks like that’s just a formality at this point. You can visit their website for more details about the mask and to get updates on future availability.

Leave a Reply

Want to join the discussion?Feel free to contribute!