Windform Used to Build Generative Orthotics

In conjunction with MHOX Design, CRP Group has created bespoke orthosis to correct misaligned limbs.

Developed over a year-long period, MHOX Design used generative design methods to create objects that can integrate appropriately with the human body.

Unlike traditional design methods that create a shape based on the designers wants, generative design uses a set of inputs and algorithms to determine a products final form.

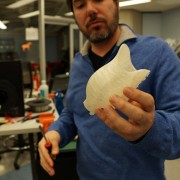

To build their new orthosis, MHOX engineers began by gathering a 3D scan of their patient’s limb. With an accurate model of their patient’s limb, designers merged that information with a unique algorithm to complete a digital model of the custom prosthetic.

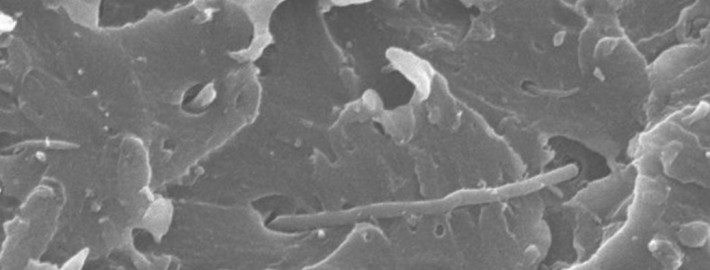

With their model in place MHOX turned to CRP Group to build a one off, completely bespoke prosthetic. Using polyamide-based Windform GT, an elastic, impermeable and durable material, CRP was able to craft an end use orthosis that performed their medical duty while also looking great.

By leveraging 3D printing MHOX Design was able to reduce the time it took to deliver their orthoses. What more, because of the accurate nature of 3D scans their prosthetic fit their customers perfectly… or rather, like a glove.

Image Courtesy of Windform – Source: http://www.engineering.com/

Leave a Reply

Want to join the discussion?Feel free to contribute!