The 3D printable finger splint and other low-cost medical devices

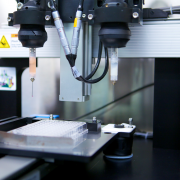

After last week life saving 3D printed device, medical 3D printing draws once again attention. A high school student in New Jersey, Ian McHale, just created a finger splint that can be produced with a 3D printer. The goal behind this initiative is to show that 3D printing can help solve concrete problems with minimal ressources.

The high school student, designed the splint on a CAD program, and made it so it can be printed in about 10 minutes for about 2 cents of recycled material.

McHale stated:

“Finger splints can come in many shapes and sizes. A finger splint immobilizes a finger or joint after an injury. Countries with restricted economies and open boarders may use this type of “Field Splint” as a convenient and inexpensive temporary stabilization device. This file describes a “Field Splint” that can be scaled on any axis and printed using ABS Plastic. Depending on the platform up to 30-40 splints can be printed in one “Run”. Each of these can be scaled independently. ”

While 3D printing still is relatively expensive, the project showed that it is possible to use this technology to create very efficient low-tech medical device. All you need is a low-end 3D printer, a 3D file and some recycled plastic.

For its design, McHale won a prize at the Mercer Science and Engineering Fair. He decided to post the designonline.

At Sculpteo, we liked this story because we often hear a few misunderstandings on 3D printing. Seeing a high-school student creating this kind of objects with just a few ressources is probably one of the best exemple to fully understand the potential of 3D printing.

Source: www.3ders.org

Leave a Reply

Want to join the discussion?Feel free to contribute!