Scientists Build MicroSLA 3D Printing System for Mass Production of Nerve Repair Guides

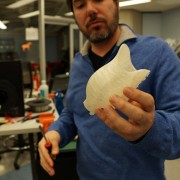

While AM in mechanical mass production (especially in the aerospace sector) is seeking larger build sizes, the opposite is true for the medical field. Here it will be the extremely small and complex parts that will drive the adoption of 3D printing technologies in mass production. One example is the Nerve Guidance Conduits (CNG) developed by a team of scientists through the use of a MicroStereolithography (MicroSLA or µSL) system.

The project, recently published in the Biomaterials Journal, sees a team of researchers, mainly from the University of Sheffield, seeking to develop support systems to favor the regeneration of the peripheral nervous system in case of severe injuries (such as injuries from car accidents or a chainsaw and, generally, up to a few millimeters). While the peripheral nervous system does have some regeneration capabilities, current methods – which include autografting and other available CNG’s – either have limited availability or limited efficiency. The 3D printed CNG’s work in a surprisingly simple way: they are implanted in the body and simply channel the nerves stimulating their growth and regeneration in order to “close the gap” between the nerve’s severed parts.

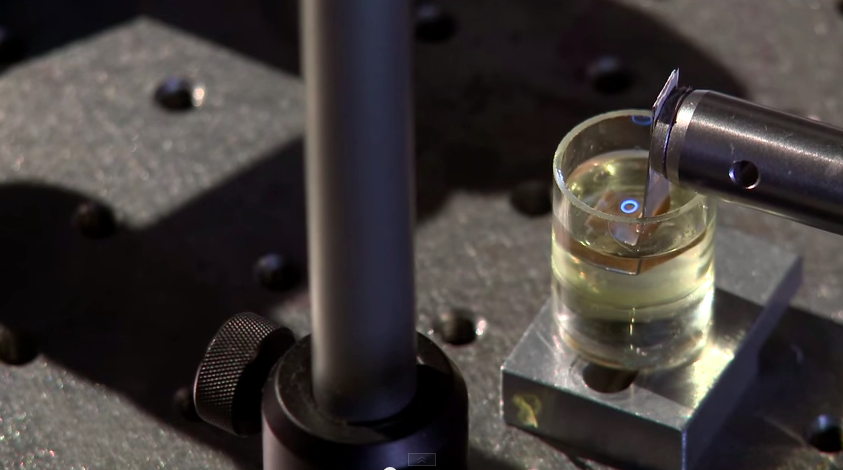

The study describes a process that is revolutionary in many ways. The first is the fact that the team developed their own MicroSLA system to produce the conduits. This means that they were able to create 3D structures with a resolution of 50 µSL using a CAD model, a photo-curable liquid (pre-polymer) resin, and a laser as an optical source. In this case the complexity was due to the fact that the conduits were extremely small and thin, but many other complex shapes are possible, as well.

Another interesting innovation is that, leveraging on previous work on both µSL and two photon polymerisation (a process for nanoscale stereolithography) the scientists used polyethylene glycol (PEG) diacrylate as a curable material. Current synthetic NGC materials include polylactic acid (PLA) and its derivatives or polycaprolactone, while collagen is a naturally derived alternative and spider silk is being investigated. Though PEG is not typically conducive for cellular attachment, its photocurable form used in the experiment allowed neuronal growth and experimental differentiation in vitro.

Overall the study demonstrated that µSL is an ideal process for the production of precise and intricate nerve guide structures which permit individual customization in order to optimize efficiency. Furthermore, the scientists behind the project calculated that it took only a few minutes to produce one NGC, which means that, with a larges size machine, it would be easier, faster, and more efficient to mass produce the nerve guidance systems, rather than to produce them by any other method.

The “magic” of 3D printing is that, through complex processes and technologies, it can paradoxically help us simplify production of anything, even something as apparently complex as a nerve repair system. Perhaps, this video will contribute to make this concept even clearer.

Source: 3dprintingindustry.com

Leave a Reply

Want to join the discussion?Feel free to contribute!