Chinese Conduct 3D Printed Spinal Implant Trials in Humans

Peking University Third Hospital in Beijing is in the process of conducting human clinical trials with titanium 3D printed spinal inserts. “We started clinical trials on 3D printed implants late last year, and now we have used dozens of such implants for more than 50 patients,” said Dr. Liu Zhongjun who is spearheading the project.

Dr. Zhongjun, who has studied in the U.S., U.K., Canada and China, is Chairman of the Department of Orthopedic surgery and the Research Center of Spinal Surgery at Peking University. He specializes in the treatment of spinal disorders and is an advocate of 3D printing.

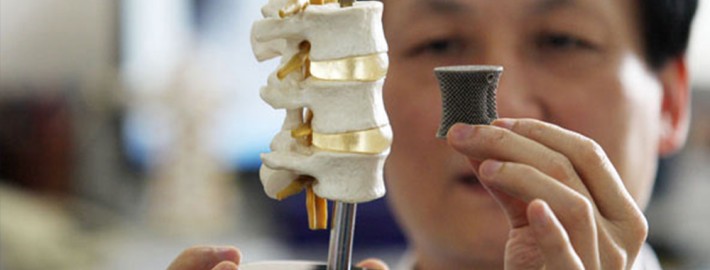

“3D printing technology has two very nice features: One, It can print specific structures; Two, it is capable of producing porous metal.” Dr. Zhongjun explained, also stating that the new 3D printed titanium implants are superior to non-printed implants because their porous design allows the surrounding bone to meld with the implant; something that isn’t possible with the technology currently in use. “In this aspect, 3D printed implants are more reliable than traditional ones,” Dr. Zhongjun said. “In the past we used clinical titanium mesh, but with the growth of bone, titanium mesh could easily stick into the bone and cause collapse. 3D printed implants fit the bone completely. And as a result, not only the pressure on the bone is reduced, but it also allows the bone to grow into the implants.”

Over the past four years Dr. Zhongjun has been working in conjunction with a medical device company that owns an imported 3D printer. In 2009 they developed the first implants and in 2010 they began animal testing with sheep. Those trials proved successful and this year they were able to apply for and get permission to begin human testing.

So far the results of the human trials have all been positive. “All the patients recover very well. Nobody seems to have any undesirable side effects or adverse reaction.”

Titanium has been used in orthopedic implants for decades, but 3D printing is allowing researchers to stretch the boundaries of known treatment options. Dr. Zhongjun and his team are able to produce completely personalized implants that fit the shape of their patient’s bodies.

Peking University’s team is using an Electron Beam Melting (EMB) 3D Printer to produce their implants. If you’d like to know more about how EMB works to produce titanium implants, you can watch the video below.

Scientists at Cornell University are also working with 3D printed spinal implants and they are almost ready for human trials. Their process is a bit different than Dr. Zhongjun’s. Instead of using titanium, they are 3D printing stem cells into dissolvable scaffolds which eventually renew the damaged section of the patient’s spine.

Source: 3dprinterworld.com

Leave a Reply

Want to join the discussion?Feel free to contribute!