Solving a Runner’s Challenge with Unprecedented Orthotics

Outdoor activities can bring a lot of enjoyment to people’s lives, and it can literally be devastating when the things we love most are no longer possible. Terry Gumbley, an active off-road runner and gardener, discovered this first hand when knee and ankle pain forced him to give up his favorite activities. Thanks to Peacocks Medical Group, with support from Materialise’s3-matic software, Terry ultimately received an orthotic that eliminated his pain, got him back on his feet, and enabled him to once more enjoy life and his garden.

Debilitating Knee and Ankle Pain

As a resident of Northeast England, Terry always made it a priority to enjoy the great outdoors, and was surprised, when one afternoon his usual activities triggered pain in one of his knees and ankles. As the pain progressively got worse, making even walking difficult, a visit to a podiatrist revealed that over pronation was the cause. It was determined that Terry’s ankle and knee needed to be slightly realigned to correct the issue. For Terry, the challenge was not just to correct the over pronation and eliminate the pain, but to ensure that it wouldn’t return when he went back to his favorite hobbies.

Supporting an Unprecedented Solution

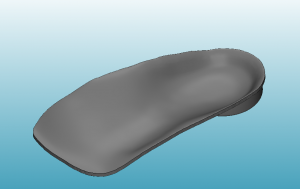

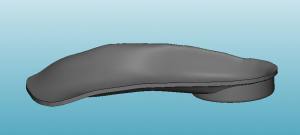

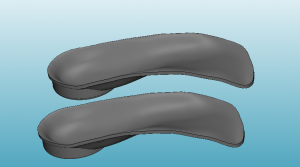

Design of orthopaedic insoles in 3-maticThe podiatrist created a prescription for an orthopaedic insole, and Peacocks Medical Group was selected for the fulfillment. Traditionally, foot orthoses are handmade using plastic and thermoplastics or milled from foam or polypropylene blocks, but both of these methods offer limited solutions.

However, Peacocks Medical, which has been providing medical equipment and solutions for over 100 years, focuses on the use of cutting-edge 3D Printing technology, alongside traditional methods, and can create Design of orthopaedic insoles in 3-maticcustomized products that are currently unprecedented in the orthotics industry.

After receiving the podiatrist’s prescription and a foam box impression of Terry’s foot, Peacocks scanned the impression, converting it into an STL file, and then performed the necessary design work using Materialise’s Design of orthopaedic insoles in 3-matic3-matic software. Once the scan was cleaned up, the scanned surfaces on the medial and lateral sides of the foot were extended to add a heel cup, and the surface under the arch was pushed up to create a small arch support. A shell was then created and a cylindrical heel added.

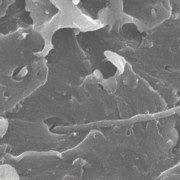

The final design was exported as an STL file and 3D Printedin nylon using Selective Laser Sintering. As a final step, the parts were finished and fitted to Terry’s feet.

Returning to the Great Outdoors

Terry found that his new insoles fit extremely well into his shoes, and locked in place, preventing any movement of the insole inside the shoe. After a few weeks, not only could he no longer feel them, but his knee and ankle pain were gone and he was back in his garden, getting closer and closer to running again. In his words:

“So far, they have been absolutely fantastic! They have been extremely comfortable right from the initial wearing. Being slightly larger than the previous orthoses, they locate better around my feet and also locate better in all of my shoes, including my slippers, which are the least supportive of any of my footwear.”

The Standard in ‘Engineering on AnatomyTM

The Mimics Innovation Suite turns 3D image data into high-quality digital models in an accurate and efficient way. Starting from optical scan, CT or MRI data, the Mimics Innovation Suite offers the most advanced image segmentation, the broadest anatomical measurement options, powerful CAD tools for Engineering on Anatomy and 3D Printing, and accurate model preparation for FEA and CFD.

In this case study, the authors used the Mimics Innovation Suite to create customized orthopaedic insoles using the following steps:

- Convert optical scan data of both feet into an STL file

- Design patient-specific orthopaedic insoles on the STL file

- Print the design in nylon using Selective Laser Sintering

Source: materialise.com

Leave a Reply

Want to join the discussion?Feel free to contribute!